| Welcome to Sprocket School! This project is maintained by volunteer editors. Learn more about how this works. |

Xenon short-arc lamp

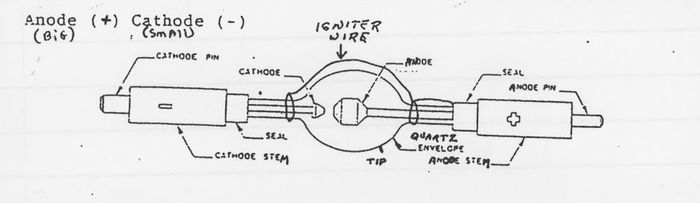

A xenon short-arc lamp is a light source used for projection. Light is produced by electricity arcing between tungsten electrodes in a quartz envelope that contains highly compressed xenon gas. Most of the light is generated by a plasma ball that forms at the tip of the cathode. For maximum light output, the lamp is aligned so that this plasma ball is positioned as close as possible to the focal point of the reflector. This is one of the steps taken to calibrate overall optical alignment.

In the past, xenon lamphouses employed both vertical and horizontal lamp configurations. Vertical lamps had the benefit of a longer lifespan but were comparatively inefficient, and required an auxiliary mirror in addition to the main reflector to maximize light output. In all modern lamphouses, the lamp is installed horizontally, laying flat with the anode end pointing to the screen. Horizontal lamps have better light output and are easier to align, but they have a greater tendency to flicker because the flow of the heated xenon gas within the envelope draws the arc upward. To mitigate this, a magnet is installed below the lamp to stabilize the arc.1

The quality of light emitted from a xenon lamp closely resembles that of natural sunlight.

History

The first xenon lamphouse premiered in West Germany in 1954. By 1969, 50% of theaters in West Germany and 15% of theaters in the United States used xenon lamps. 2 Xenon arc lamps rose to popularity in the United States in the 1970s as part of the industry-wide movement towards greater automation. They replaced the far more labor-intensive carbon arc lamphouses previously in use, which had to be monitored and adjusted by a dedicated projectionist during every show. Xenon lamps facilitated further automation by making it easier for operators to build film up to large reels and platters, which was difficult or impossible with carbon arc because the maximum uninterrupted run time for a single projector was limited by carbon burn rate and by the maximum travel distance of the carbon feed mechanism. By the 1980s, xenon lamps were the near-universal standard for theatrical projection.

Use

General recommendations

- After the lamp is struck it takes 3-5min for the arc to stabilize. Strike the lamp a few minutes before starting playback to ensure a good picture.

- Striking a lamp once causes about as much wear as running the lamp for an hour. When running reel-to-reel, the lamps should not be turned off between reels.

- Never run the lamp without ventilation, and run the blower for at least a 10min cooldown period after the lamp has been powered down.

- Always strike a lamp with the hand dowser closed.

- Xenon lamps are highly pressurized and can explode. Full safety gear and proper training is required to replace or handle xenon lamps in any way.

- Lamp alignment takes place within the closed lamphouse and is safe to do without safety gear. Lamp alignment is one of the top neglected things in a projection booth and must be done whenever a lamp is replaced.

Lamp sizes

Xenon lamps come in a variety of sizes, each designed to operate within a specific wattage range. The size of the lamp to be used in a given installation will depend on the illumination requirements and the electrical rating of the lamphouse. Adapters can be fitted to the anode and cathode ends of a lamp to allow it to fit different lamphouse models. As a lamp ages it requires more power to reach the same light output, so the power draw must be increased over the life of the lamp. When selecting the right lamp for a given installation, it must be able to maintain its brightness target for the duration of its lifespan.

When using larger lamps, precautions must be taken to prevent heat damage to the film. The reflector should be a dichroic mirror, and a heat shield should be installed to filter out UV light. When running 35mm, the projector should be equipped with a water-cooled gate for lamps exceeding 3kW. Regulating heat is even more important when running 16mm, because the light is focused on a smaller surface area. Film can also be damaged by a lamp that is misaligned, creating a hotspot that blisters (see "embossing" below) one portion of the frame.

-

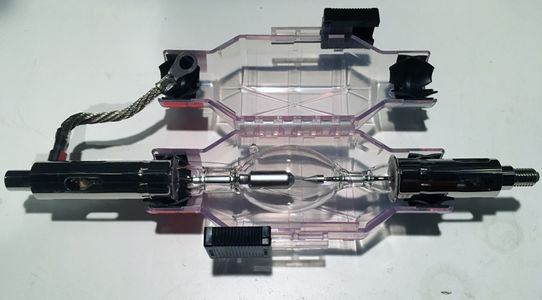

A 1.2kW Ushio xenon lamp in its shield.

-

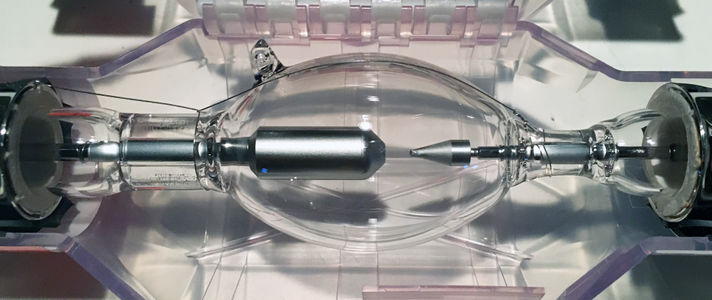

This lamp was removed at the end of its warranty. There is visible wear on the cathode.

Lamp Alignment

Whenever a new xenon lamp is installed it must be properly aligned on the X, Y and Z axis (horizontal, vertical, axial) to have even illumination and achieve the proper luminance on screen. Poor lamp alignment can result in hot spots of light on screen, damage the reflector, lens, and even the print. A lamp alignment should be performed when a new lamp is installed and periodically thereafter because the position may drift over time.

Lamp alignment should be done whenever a new lamp is installed. Lamp alignment should also be checked if you see hot spots or shadows on screen or if you discover embossing or burns on prints that you have run. If you are switching between different film gauges on the same projector, the position of the reflector should be adjusted to achieve the correct working distance between the focal point of the reflector and the aperture. Most dual format lamphouses have a toggle switch to make this adjustment.

Most lamphouses have a mechanical adjustment to shift the position of the cathode end, while the anode end is supported by a post or yoke with an adjustable height. The height of the anode can usually be set during the initial installation, with only the cathode end being adjusted at every lamp change. If you center the cathode end, it will be apparent if the anode position is incorrect because the lamp will not be straight.

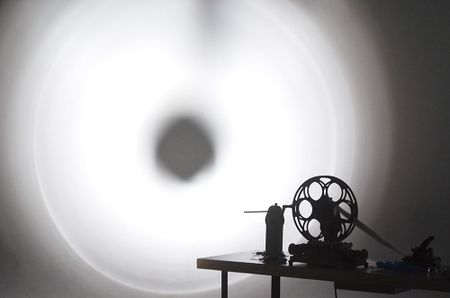

During alignment you will see the following on screen: The shadow of the anode assembly at the end of the lamp is the dark circle, immediately ringed by visible plasma (the electron arc). Surrounding it is the circle of light collected by the reflector, and reflected upon the screen. This area comprises most of what we see, and should appear bright white and essentially even in luminance upon completion of the alignment.

Lamp Alignment Steps

1. Turn on exhaust, make sure lamphouse dowser is closed. Always have lamphouse dowser closed before striking a lamp. Striking a lamp with the motor off and the lamphouse dowser open can melt the shutter blades and changeover dowser, and can crack the lens.

2. Remove lens (Kinoton users should remove the skate so that it isn't damaged by the heat). Turn on lamp. Start motor and open dowser.

3. Make the axial adjustment (the “focus” on the Z axis) til you see a circle with a little bit of plasma around the edges of the anode shadow (people call this “the eye”).

4. Make your horizontal and vertical adjustments until you get as close to a symmetrical circle as possible.

5. Re-adjust the axial alignment to bring the plasma back into focus, until you have a tight symmetrical circle free of light (plasma) fluttering around the anode shadow.

6. Put in a lens (CinemaScope is usually best as you want the largest aperture). After you put the lens back in look for even illumination across the screen. With the lens in, the shadows will be gone and there will be a hotspot in the center of the screen. Focus the lamp (making fine X and Y axis adjustments as necessary) until no shadows are visible at the corners and the illumination is even across the screen. You want it bright, flat and centered with no hot spots! Changeover from projector 1 to projector 2. You want them to look as similar as possible.

7. You may want to fine-tune the lamp focus with the lens in place until you have even illumination, then take the lens out again to check the symmetry of the anode shadow.

WARNING: The heat from the lamp can crack the glass of the lens when there’s no film in the gate, so the dowser can only be opened for brief periods during the alignment. For a 2kW lamp, the dowser should be opened for no more than 30 seconds at a time, with breaks between for the lens to cool down. For large lamps, use quick bursts of light and a long cooldown period. Consult your service technician before making these adjustments!

8. Finally, take a light reading with your luminance meter.

Measuring Luminance

The SMPTE specification is 16fL (foot lamberts) with uniform illumination across the projected area without film in the projector (open gate). Because the 1.85:1 "Flat" aspect ratio uses the smallest aperture it is the least light efficient, while 1.33:1 silent or 2.39:1 CinemaScope apertures are the most light efficient. You can split the difference by using 15fL for 1.85:1 and 17fL for Cinemascope to achieve a balance within SMPTE specifications.

In most circumstances a fixed-height screen will evenly balance the light output between the smallest aperture (1.85:1) and the largest aperture (typically 2.39:1) because the greater light output from the CinemaScope frame is used to illuminate a larger screen area. However, this is complicated by movable vertical masking. When the height of the screen can be increased for narrower formats, the light requirements can vary dramatically. Stopdown rings can also be used to reduce the light output of formats with a larger aperture (1.33 or 1.37) to achieve the necessary balance of light output between aspect ratios.

If you’re checking luminance through the port glass with your meter, subtract 1~2fL from the reading. It’s always best to take your final readings in the auditorium itself.

Potential Issues

- If you can’t evenly distribute the plasma with lamp alignment (you’ll notice it will appear asymmetrical even as you adjust the focus), the arc stabilization magnet may need to be adjusted by a trained technician. Excessive flicker may result if the plasma isn’t evenly distributed.

- If dark spots appear in the area within the circle of light with the lens removed, the reflector should be inspected for pitting, explosion damage, or any other damage to the reflective coating.

- Damaged lamp

- Cannot focus lamp because of physical lamphouse alignment in relation to projector (the "working distance" between the focal point of the reflector and the aperture is incorrect)

Damage

Improper lamp alignment or lamps that are run too hot can result in permanent damage to the film print.

Embossing is a permanent deformation that occurs when prints are projected with high intensity lamps and without proper heat absorbers. The excessive heat expands the picture area, and the frame stands out in relief.

Always have lamphouse dowser closed before striking a lamp -- striking a lamp when the motor is off and the dowser open can result in the following: melted shutter blades, changeover plates, cracked heat filter glass (if installed), melted film, or cracked lenses. Some projectors have a fire dowser that only opens when the motor starts, but some do not.

Aging

Xenon lamps have a fixed arc gap, but over time the tungsten of the cathode gets burnt off by the plasma, increasing the distance between the electrodes and reducing the light emitted at a given power draw. Burnt off tungsten can also deposit on the envelope, creating black spots and accelerating the effects of aging.

Xenon lamps lose up to 40% of their luminance over time due to cathode burn back. For example, a 2kW lamp usually loses a couple foot lamberts in the first 500 hours of run time. Ideally, the lamp should be checked at its quarter-life and the voltage should be increased so that it hits its target light output.

Alternatively, if a technician is not available to make the necessary rectifier adjustment, a lamp can be installed slightly defocused so that simply focusing the lamp will correct for light drop-off at the quarter-life.

Symptoms of aging include:

- Flicker

- Failure to strike

- Blackening of the envelope

- Deformation of the electrodes

- Discoloration on the anode end (primarily when the lamphouse is poorly ventilated or the lamp is poorly focused). NOTE: This indicates excessive heat on the anode end, which can cause the anode seal to fail, resulting in premature lamp failure.

Lamp Manufacturers

Lamp Safety

The Xenon gas in cold Xenon lamps measures approximately 300 times atmospheric pressure. The Xenon gas in hot Xenon lamps measures approximately 1400 times atmospheric pressure, both of these are extremely dangerous! An exploding lamp will expel shrapnel in all directions, so a face shield and full-body protective clothing 'must be worn when handling xenon lamps. Some lamp manufacturers sell safety gear, you can also use protective clothing designed for welding.

Each theater should stock safety gear in multiple sizes. This is especially important for gloves, because ill-fitting gloves will limit dexterity and make handling the lamps more dangerous.

Lamp changes should only be done by a service technician or someone who has been properly trained by a service technician.

Safety gear should include:

- Face shield - A thick polycarbonate face shield with an adjustable head strap. A ratcheting head strap is preferred to a snap connector, since it will be easier to manipulate with gloves on.

- Jacket - A Kevlar jacket or a rawhide welding jacket that extends below the waist. The jacket should have snap or velcro fasteners.

- Gauntlets - Gauntlet-style gloves that cover the wrists. Gloves should be Kevlar-lined or leather. Kevlar gloves tend to be bulky and restrictive, and may be problematic if the lamp change procedure for your lamphouse requires delicate control of small parts. For maximum protection, gloves should be worn underneath the jacket, with the gauntlet sleeve beneath the jacket sleeve. Jackets with velcro wrist straps are even better.

- Pants - Heavy-duty work pants, thick denim, or another dense material that will protect against glass shrapnel. Pants should be full-length.

- Footwear - Leather work boots are ideal. Footwear should be made of a dense material and cover the ankles.

Never open the lamphouse or handle the lamp when it’s hot. A hot lamp is under much greater pressure than a cool lamp. Let the lamp cool for at least 10min before handling it.

Before performing a lamp change, prepare your workspace. Place the empty shield or other protective enclosure on a clean, clutter free surface with adequate room to work. It should be open and ready to receive the used lamp. Make sure you have a clear path to the lamphouse with no obstacles or tripping hazards.

Safety Gear Manufacturers

- 3M sells face shields.

- Christie offers a lamp safety kit that consists of a face shield, Kevlar jacket, and gloves.

- Any vendor of welding gear can provide heavy-duty leather jackets and gloves.

Disposal of xenon lamps

To safely dispose of a xenon lamp, the glass vessel must be depressurized or destroyed. Some service technicians will dispose of used lamps for their clients, but it can be difficult to find a third-party company who will do so, forcing many theaters to dispose of them in-house. This should only be done by trained personnel with adequate safety gear.

As an added concern, the lamp cathodes contain a small amount of the radioactive element thorium, so local regulations should be followed when disposing of them.

Before you consider disposing of xenon lamps at your theater, consult with your service technician and contact the lamp manufacturer to see if they offer a disposal service or recycling program.

Safety Considerations

Regardless of how a lamp is destroyed, an effort must be made to minimize the risk to the individual handling the lamp and anyone else who might be in the vicinity. Depressurizing lamps is more dangerous and requires special tools, so destroying a lamp by shattering the envelope is the easiest method. This can be done by enclosing the lamp in a protective container and dropping it.

WARNING: When the envelope is shattered, the lamp will explode. If the lamp is not fully contained, the glass shrapnel can travel a considerable distance.

Recommended precautions:

- Wear full safety gear: Polycarbonate face shield, leather or kevlar-lined jacket and gauntlets, protective pants and shoes, etc.

- Destroy lamps in a safe, controlled environment. Inform the staff on duty (and anyone who may arrive during disposal) and restrict foot traffic to the area. Consider locking doors or posting signs to notify people of the danger. It is advisable to dispose of lamps outside of the regular hours of operation. Do NOT destroy lamps in the projection booth.

- The lamp should be enclosed in a protective container. For lamps that ship in a hard ballistic shield, the original shield can be used, but be aware that shrapnel will be expelled from the anode and cathode openings. For added security, wrap the shield with packing tape to prevent it from opening when dropped. For bulbs shipped in a thin sheet of polycarbonate or a fabric wrap, a solid wooden box can be constructed.

- The individual destroying the lamp should have have a physical barrier to take cover behind.

- Listen for the pop that indicates the lamp has exploded. If it does not explode on the first attempt, take caution when approaching the lamp to throw it again (treat it like a lit firework that failed to ignite but might still go off).

- After lamp disposal, take care to thoroughly clean the area and remove all glass shards.

Manufacturer recommendations

Osram

- Osram lamps ship in a foam support, with the lamp wrapped in a piece of fleece that is secured with fabric ties. To dispose of used lamps, they recommend wrapping them in the original protective cloth, with the straps wrapping the fabric tightly against the anode and cathode bases, then dropping them from a height of 1-2 meters.[3]

Ushio

- Ushio lamps ship in a ballistic shield, with the anode and cathode ends supported by cardboard blocks. To dispose of used lamps, Ushio recommends returning the lamp to its original shield and box and dropping it from a height if three feet.[4]

- In practice, their packaging is secure enough that it can be very difficult to destroy the lamp in this fashion.

Resources

See Also

References

- Torkell Sætervadet, The Advanced Projection Manual: Projecting Classic Films in a Modern Projection Environment (Oslo: The Norwegian Film Institute and the International Federation of Film Archives, 2006), 41; Bernard Happé, ed., Motion Picture Presentation Manual: A Comprehensive Handbook of Projection Practice, rev. ed. (London: The British Kinematograph, Sound and Television Society, 1979), 57.

- Don V. Kloepfel, ed., Motion-Picture Projection and Theatre Presentation Manual (Scarsdale, NY: Society of Motion Picture and Television Engineers, Inc., 1969), 66-67.

- Osram Group, XBO lamp catalog (PDF), April 11, 2018. https://media.osram.info/im/img/osram-dam-2173907//XBO_brochure_(EN).pdf.

- Ushio America, Inc, "Xenon Arc Lamp Disposal," Lamp Safety & Technical Resources, accessed February 11, 2019, https://www.ushio.com/support/lamp-safety-and-technical-resources/#toggle-id-6.